#greenchemistry #ammoniaproduction #sustainableenergy #cleanenergy #chemicalengineering #lithiumtechnology #hydrogenfuel #renewableenergy

Engineers at the University of Illinois Chicago have pioneered an innovative update to the process of ammonia production, shedding new light on a more environment-friendly pathway by coordinating a unique interaction between lithium, nitrogen, and hydrogen atoms. This advancement, detailed in a recent publication in the ACS Applied Materials & Interfaces journal, has the potential to drastically reduce the carbon footprint associated with ammonia manufacture, which is traditionally energy-intensive and ranks high in terms of carbon emissions next to cement production.

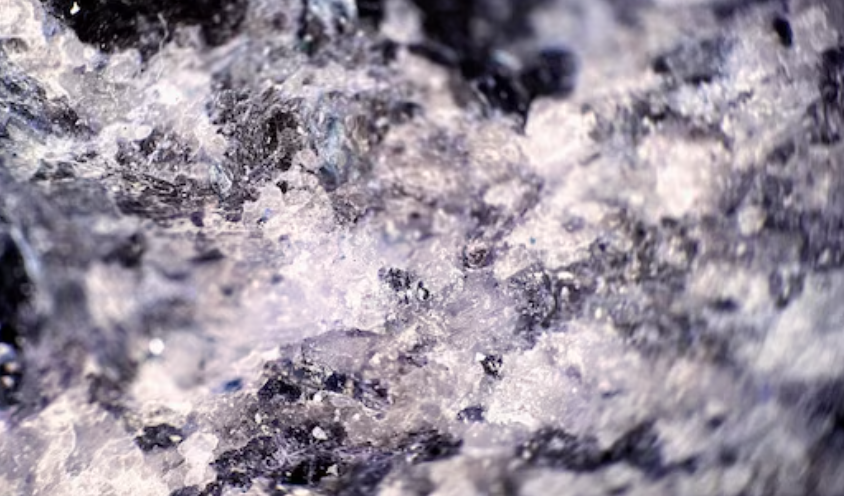

Traditionally, ammonia’s synthesis requires cracking nitrogen gas molecules using high temperatures and pressures, a process responsible for significant carbon emissions. However, the team’s novel approach, termed lithium-mediated ammonia synthesis, circumvents this by facilitating the direct combination of nitrogen gas and a hydrogen-donating fluid, such as ethanol, in the presence of a charged lithium electrode. This method significantly lowers the required operational temperatures and energy inputs, thereby offering a greener alternative.

This process stands out not only for its lower temperature operation but also for its regenerative nature. It allows for the recycling of the initial reactants, lithium and the hydrogen source, through a cyclic process likened to a “symphony” by the team’s lead researcher, Meenesh Singh. This efficient cyclical mechanism ensures the sustainable production of ammonia with potential implications on both cost and environmental impact.

The engineering team is building on a reaction mechanic known for almost a century and focusing on optimizing the cycle to achieve economical viability alongside environmental benefits. Their method projects the cost of ammonia production at $450 per ton, a figure 60% lower than earlier lithium-based and other green methodologies, while maintaining selectivity and energy efficiency that align with the Department of Energy’s standards for large-scale production.

Beyond reducing emissions, this innovative technique could revolutionize hydrogen storage and transportation, utilizing ammonia as a safe and efficient hydrogen carrier. This aspect is particularly significant for the renewable energy sector, where hydrogen plays a pivotal role.

The initiative to pilot and scale this lithium-mediated ammonia synthesis process is underway, in collaboration with the General Ammonia Co., marking a promising step towards sustainable industrial chemistry and a cleaner, greener future.

Comments are closed.